Ukuthuthukiswa kwemboni yesimanje kuye kwafaka izidingo ezikhulayo endaweni yokuhlola, ucwaningo nokukhiqiza. Indlela eyinhloko yokufeza le mfuneko ukusebenzisa kabanzi izihlungi zomoya ezinhlelweni ezihlanzekile zomoya. Phakathi kwazo, izihlungi ze-HEPA ne-ULPA ziyisivikelo sokugcina sezinhlayiya zothuli ezingena egumbini elihlanzekile. Ukusebenza kwayo kuhlobene ngokuqondile nezinga legumbi elihlanzekile, elithinta inqubo kanye nekhwalithi yomkhiqizo. Ngakho-ke, kunengqondo ukwenza ucwaningo lokuhlola kusihlungi. Ukusebenza kokumelana nokusebenza kokuhlunga kwezihlungi ezimbili kuqhathaniswe ngesivinini somoya esihlukile ngokulinganisa ukusebenza kahle kokuhlunga kwesihlungi se-fiber yengilazi kanye nesihlungi se-PTFE sezinhlayiyana ezingu-0.3 μm, 0.5 μm, 1.0 μm PAO. Imiphumela ibonisa ukuthi isivinini somoya siyisici esibaluleke kakhulu esithinta ukusebenza kahle kokuhlunga kwezihlungi zomoya ze-HEPA. Ukuphakama kwesivinini somoya, kunciphisa ukusebenza kahle kokuhlunga, futhi umphumela uba sobala kakhulu kuzihlungi ze-PTFE.

Amagama angukhiye:Isihlungi somoya se-HEPA;Ukusebenza kokumelana; ukusebenza kokuhlunga; Iphepha lokuhlunga le-PTFE; iphepha lokuhlunga ingilazi ye-fiber; isihlungi se-fiber glass.

Inombolo ye-CLC:X964 Ikhodi yokuhlonza idokhumenti: A

Ngokuthuthuka okuqhubekayo kwesayensi nobuchwepheshe, ukukhiqizwa nokwenziwa kwesimanje kwemikhiqizo yezimboni yesimanje kuye kwadingeka kakhulu ngokuhlanzeka komoya wasendlini. Ikakhulukazi, i-microelectronics, imithi, amakhemikhali, i-biological, ukucubungula ukudla nezinye izimboni zidinga i-miniaturization. Ukunemba, ukuhlanzeka okuphezulu, ikhwalithi ephezulu kanye nokwethenjwa okuphezulu kwendawo yasendlini, ebeka izidingo eziphakeme neziphakeme ekusebenzeni kwesihlungi somoya se-HEPA, ngakho-ke indlela yokwenziwa kokuhlunga kwe-HEPA ukuze kuhlangatshezwane nesidingo sabathengi sekuyisidingo esiphuthumayo sabakhiqizi. Enye yezinkinga ezixazululiwe [1-2]. Kwaziwa kahle ukuthi ukusebenza kokumelana nokusebenza kahle kokuhlunga kwesihlungi kuyizinkomba ezimbili ezibalulekile zokuhlola isihlungi. Leli phepha lizama ukuhlaziya ukusebenza kokuhlunga nokusebenza kokumelana kwesihlungi somoya se-HEPA sezinto zokuhlunga ezihlukene ngokuhlolwa [3], kanye nezakhiwo ezihlukene zezinto ezifanayo zokuhlunga. Ukusebenza kokuhlunga kanye nezici zokumelana nesihlungi kunikeza isisekelo sethiyori somkhiqizi wokuhlunga.

1 Ukuhlaziya indlela yokuhlola

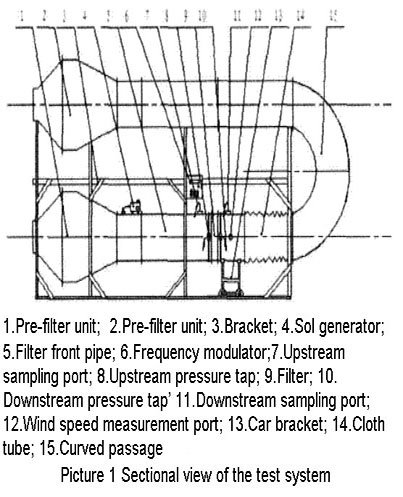

Ziningi izindlela zokuthola izihlungi zomoya ze-HEPA, futhi amazwe ahlukene anamazinga ahlukene. Ngo-1956, Ikhomishini Yezempi Yase-US yasungula i-USMIL-STD282, izinga lokuhlola isihlungi somoya se-HEPA, kanye nendlela ye-DOP yokuhlola ukusebenza kahle. Ngo-1965, i-BS3928 ejwayelekile yaseBrithani yasungulwa, futhi indlela ye-sodium flame yokuthola ukusebenza kahle yasetshenziswa. Ngo-1973, i-European Ventilation Association yathuthukisa izinga le-Eurovent 4/4, elilandela indlela yokuthola ilangabi le-sodium. Kamuva, i-American Society for Environmental Testing and Filter Efficiency Science yahlanganisa uchungechunge lwamazinga afanayo ezindlela zokuhlola ezinconyiwe, zonke zisebenzisa indlela yokubala ye-DOP caliper. Ngo-1999, iYurophu yasungula indinganiso ye-BSEN1822, esebenzisa usayizi wezinhlayiyana osobala kakhulu (MPPS) ukuze ibone ukusebenza kahle kokuhlunga [4]. Izinga lokutholwa laseChina lamukela indlela ye-sodium flame. Isistimu yokuthola ukusebenza kwesihlungi somoya se-HEPA esetshenziswe kulokhu kuhlola ithuthukiswe ngokusekelwe kuzinga le-US 52.2. Indlela yokuthola isebenzisa indlela yokubala i-caliper, futhi i-aerosol isebenzisa izinhlayiya ze-PAO.

1. 1 insimbi eyinhloko

Lokhu kuhlolwa kusebenzisa izinto zokubala zezinhlayiyana ezimbili, ezilula, ezilula, ezisheshayo futhi ezinembile uma kuqhathaniswa nezinye izinto zokuhlola ukugxiliswa kwezinhlayiyana [5]. Izinzuzo ezingenhla zekhawunta yezinhlayiyana ziyenza kancane kancane ithathele ezinye izindlela futhi ibe indlela yokuhlola eyinhloko yokugxila kwezinhlayiyana. Bangakwazi ukubala kokubili inani lezinhlayiya kanye nokusabalalisa usayizi wezinhlayiyana (okungukuthi, ukubala ukubala), okuyisisetshenziswa esiyinhloko salokhu kuhlolwa. Izinga lokugeleza kwesampula ngu-28.6 LPM, futhi iphampu yayo yevacuum engena-carbon inezici zomsindo ophansi nokusebenza okuzinzile. Uma inketho ifakiwe, izinga lokushisa kanye nomswakama kanye nesivinini somoya kungalinganiswa futhi isihlungi singahlolwa.

Isistimu yokuhlonza isebenzisa ama-aerosols isebenzisa izinhlayiya ze-PAO njengothuli oluzohlungwa. Sisebenzisa amajeneretha e-aerosol (isizukulwane se-Aerosol) yemodeli ye-TDA-5B ekhiqizwe e-United States. Ububanzi bokwenzeka yi-500 - 65000 cfm (1 cfm = 28.6 LPM), futhi ukugxila ngu-100 μg / L, 6500 cfm; 10 μg / L, 65000 cfm.

1. 2 igumbi elihlanzekile

Ukuze kuthuthukiswe ukunemba kokuhlolwa, ilabhorethri yeleveli engu-10,000 yaklanywa futhi yahlotshiswa ngokuvumelana ne-US Federal Standard 209C. I-coating floor isetshenziswa, ebonakala ngezinzuzo ze-terrazzo, ukumelana nokugqoka, ukubekwa uphawu okuhle, ukuguquguquka kanye nokwakhiwa okuyinkimbinkimbi. Izinto ezibonakalayo ziyi-epoxy lacquer futhi udonga lwenziwe ngegumbi elihlanzekile elihlanganisiwe. Ikamelo ifakwe 220v, 2×40w ukuhlanzwa 6 izibani futhi ihlelwe ngokuvumelana nezidingo zokukhanyisa kanye nemishini yasensimini. Igumbi elihlanzekile linezindawo zomoya ezi-4 eziphezulu kanye nezimbobo zokubuyisela umoya ezingu-4. Igumbi leshawa yomoya lenzelwe ukulawula okukodwa okujwayelekile kokuthinta. Isikhathi seshawa yomoya singu-0-100s, futhi isivinini somoya sanoma iyiphi umlomo wombhobho wevolumu yomoya eshintshwayo sikhulu noma silingana no-20ms. Ngenxa yokuthi indawo yegumbi elihlanzekile ingu-<50m2 futhi abasebenzi bangabantu abangu-5, indawo ephephile inikezwa igumbi elihlanzekile. Isihlungi se-HEPA esikhethiwe yi-GB01×4, ivolumu yomoya ingu-1000m3/h, futhi ukusebenza kahle kokuhlunga kukhulu noma kulingana no-0.5μm no-99.995%.

1. 3 amasampula okuhlola

Izinhlobo zesihlungi se-fiber yengilazi yilezi: 610 (L) × 610 (H) × 150 (W) mm, uhlobo lwe-baffle, imibimbi engama-75, usayizi 610 (L) × 610 (H) × 90 (W) Mm, nama-pleats angu-200, PTFE usayizi wesihlungi 480 × 8 mm (H) (H) uhlobo lwe-baffle, olunemibimbi eyi-100.

2 Izimiso eziyisisekelo

Umgomo oyisisekelo webhentshi lokuhlola ukuthi ifeni ishaywa emoyeni. Njengoba i-HEPA/UEPA ifakwe nesihlungi somoya se-HEPA, kungacatshangwa ukuthi umoya usuphenduke umoya ohlanzekile ngaphambi kokufinyelela ku-HEPA/UEPA ehloliwe. Idivayisi ikhipha izinhlayiya ze-PAO epayipini ukuze yenze ukugxiliswa okufiswayo kwegesi equkethe uthuli futhi isebenzisa isibali sezinhlayiyana ze-laser ukuze sinqume ukugxiliswa kwezinhlayiyana. Igesi equkethe uthuli ibe isigeleza ku-HEPA/UEPA ehloliwe, futhi ukugxiliswa kwezinhlayiyana zothuli emoyeni ehlungwe yi-HEPA/UEPA nakho kukalwa kusetshenziswa isibali sezinhlayiyana ze-laser, futhi ukugcwala kothuli komoya ngaphambi nangemuva kwesihlungi kuqhathaniswa, ngaleyo ndlela kunqunywe i-HEPA/UEPA. Ukusebenza kokuhlunga. Ngaphezu kwalokho, izimbobo zamasampula zihlelwa ngokulandelana ngaphambi nangemuva kwesihlungi, futhi ukumelana kwesivinini somoya ngasinye kuhlolwa kusetshenziswa igeji ye-tilt micro pressure lapha.

3 ukuqhathaniswa kokusebenza kokumelana nesihlungi

Isici sokumelana ne-HEPA singenye yezimpawu ezibalulekile ze-HEPA. Ngaphansi kwesisekelo sokuhlangabezana nokusebenza kahle kwesidingo sabantu, izici zokumelana zihlobene nezindleko zokusetshenziswa, ukumelana kuncane, ukusetshenziswa kwamandla kuncane, futhi izindleko zigcinwa. Ngakho-ke, ukusebenza kokumelana kwesihlungi sekuyinkinga. Enye yezinkomba ezibalulekile.

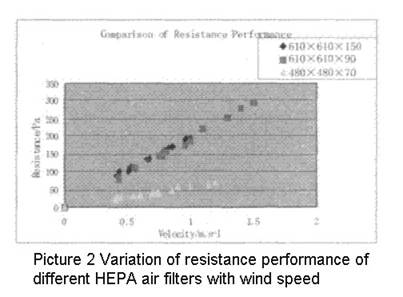

Ngokwedatha yokulinganisa yokuhlola, ubudlelwano phakathi kwesivinini somoya esimaphakathi sezihlungi ezimbili ezihlukene zesakhiwo sefayibha yengilazi nesihlungi se-PTFE kanye nomehluko wengcindezi yesihlungi uyatholwa.Ubudlelwano buboniswa kuMfanekiso 2:

Kungabonakala kudatha yokuhlola ukuthi njengoba isivinini somoya sikhula, ukumelana nesihlungi kukhuphuka ngokomugqa ukusuka phansi kuye phezulu, futhi imigqa emibili eqondile yezihlungi ezimbili zefayibha yengilazi iqondana kakhulu. Kulula ukubona ukuthi uma isivinini somoya sokuhlunga siyi-1 m/s, ukumelana nesihlungi se-fiber yengilazi cishe kuphindwe kane kwesihlungi se-PTFE.

Ukwazi indawo yesihlungi, ubudlelwano phakathi kwejubane lobuso kanye nomehluko wengcindezi yesihlungi bungatholakala:

Kungabonakala kudatha yokuhlola ukuthi njengoba isivinini somoya sikhula, ukumelana nesihlungi kukhuphuka ngokomugqa ukusuka phansi kuye phezulu, futhi imigqa emibili eqondile yezihlungi ezimbili zefayibha yengilazi iqondana kakhulu. Kulula ukubona ukuthi uma isivinini somoya sokuhlunga siyi-1 m/s, ukumelana nesihlungi se-fiber yengilazi cishe kuphindwe kane kunesehluzo se-PTFE.

Ukwazi indawo yesihlungi, ubudlelwano phakathi kwejubane lobuso kanye nomehluko wengcindezi yesihlungi bungatholakala:

Ngenxa yomehluko phakathi kwejubane eliphezulu lezinhlobo ezimbili zokuhlunga kanye nomehluko wengcindezi yokuhlunga yamaphepha amabili okuhlunga, ukumelana nesihlungi esinencazelo engu-610 × 610 × 90mm ngesivinini esifanayo kuphezulu kunokucaciswa okungu-610 ×. Ukumelana nesihlungi esingu-610 x 150mm.

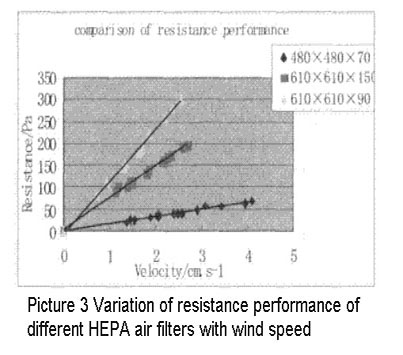

Kodwa-ke, kusobala ukuthi ngesivinini esifanayo, ukumelana nesihlungi se-fiber glass kuphakeme kunokumelana kwe-PTFE. Kubonisa ukuthi i-PTFE iphakeme kunesihlungi se-fiber yengilazi ngokusebenza kokumelana. Ukuze uqonde kabanzi izici zesihlungi se-fiber yengilazi kanye nokumelana ne-PTFE, kwenziwa ezinye izivivinyo. Tadisha ngokuqondile ukumelana kwamaphepha amabili okuhlunga njengoba isivinini somoya sokuhlunga sishintsha, imiphumela yokuhlola iboniswa ngezansi:

Lokhu kuqhubeke kuqinisekisa isiphetho sangaphambilini sokuthi ukumelana kwephepha lesihlungi se-glass fiber kuphakeme kunokwe-PTFE ngaphansi kwesivinini somoya esifanayo [6].

4 ukuqhathanisa ukusebenza kwesihlungi

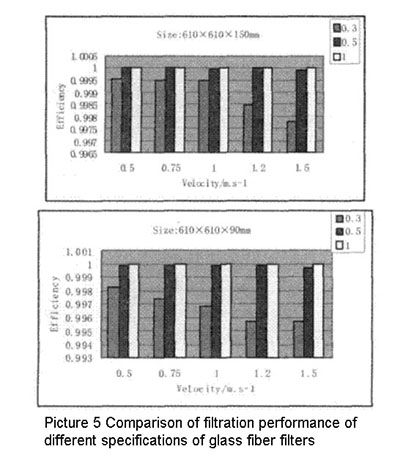

Ngokwezimo zokuhlola, ukusebenza kahle kokuhlunga kwesihlungi sezinhlayiyana ezinosayizi wezinhlayiyana ongu-0.3 μm, 0.5 μm, no-1.0 μm ngesivinini somoya esihlukile kungalinganiswa, futhi kutholwa ishadi elilandelayo:

Ngokusobala, ukusebenza kahle kokuhlunga kwezihlungi ze-glass fiber ezimbili zezinhlayiya ezingu-1.0 μm ngesivinini somoya esihlukene ngu-100%, kanye nokusebenza kahle kokuhlunga kwezinhlayiyana ezingu-0.3 μm no-0.5 μm kuncipha ngokwanda kwesivinini somoya. Kungabonakala ukuthi ukusebenza kahle kokuhlunga kwesihlungi ezinhlayiyeni ezinkulu kuphakeme kunezinhlayiya ezincane, futhi ukusebenza kokuhlunga kwesihlungi se-610 × 610 × 150 mm kuphakeme kunesihlungi sokucaciswa kwe-610 × 610 × 90 mm.

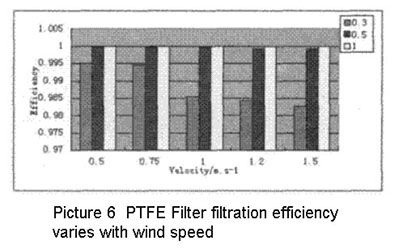

Kusetshenziswa indlela efanayo, igrafu ebonisa ubudlelwano phakathi kokusebenza kahle kokuhlunga kwesihlungi se-PTFE esingu-480×480×70 mm njengomsebenzi wesivinini somoya siyatholwa:

Ukuqhathanisa i-Fig. 5 kanye ne-Fig. 6, umphumela wokuhlunga we-0.3 μm, 0.5 μm isihlungi sengilazi yezinhlayiyana ungcono, ikakhulukazi kumphumela wokungafani wothuli ongu-0.3 μm. Umphumela wokuhlunga wezinhlayiya ezintathu ezinhlayiyeni eziyi-1 μm wawungu-100%.

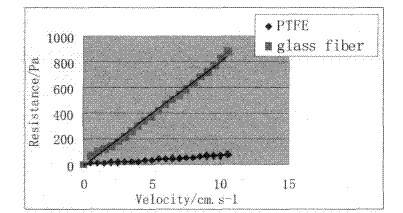

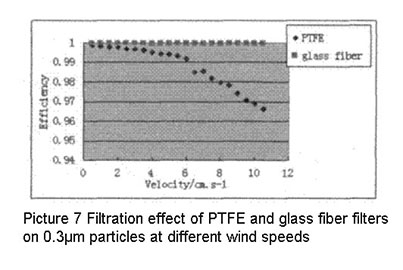

Ukuze uqhathanise ngokunembile ukusebenza kokuhlunga kwesihlungi se-fiber yengilazi kanye nezinto zokuhlunga ze-PTFE, ukuhlolwa kokusebenza kwesihlungi kwenziwa ngokuqondile kumaphepha amabili okuhlunga, futhi ishadi elilandelayo latholwa:

Ishadi elingenhla litholwa ngokulinganisa umphumela wokuhlunga we-PTFE kanye nephepha lesihlungi se-fiber yengilazi ezinhlayiyeni ezingu-0.3 μm ngesivinini somoya esihlukile [7-8]. Kusobala ukuthi ukusebenza kahle kokuhlunga kwephepha lokuhlunga le-PTFE liphansi kunalelo lephepha lesihlungi sengilazi.

Uma ucabangela izakhiwo zokumelana nezinto zokuhlunga zezinto zokuhlunga, kulula ukubona ukuthi izinto zokuhlunga ze-PTFE zifaneleka kakhulu ukwenza izihlungi ezimahhadla noma ezingaphansi kwe-HEPA, kanye nezinto zokuhlunga ingilazi ze-fiber ezifanele kakhulu ukwenza izihlungi ze-HEPA noma ze-Ultra-HEPA.

5 Isiphetho

Amathemba ezinhlelo zokusebenza ezihlukene zokuhlunga ayahlolwa ngokuqhathanisa izakhiwo zokumelana nezici zokuhlunga zezihlungi ze-PTFE ngezihlungi ze-glass fiber. Kusukela ekuhloleni singafinyelela isiphetho sokuthi isivinini somoya siyisici esibaluleke kakhulu esithinta umphumela wokuhlunga wesihlungi somoya se-HEPA. Ukuphakama kwesivinini somoya, kwehlisa ukusebenza kahle kokuhlunga, umphumela osobala kakhulu kusihlungi se-PTFE, futhi jikelele Isihlungi se-PTFE sinomphumela ophansi wokuhlunga kunesihlungi se-fiberglass, kodwa ukumelana kwaso kuphansi kunokwesihlungi se-fiber glass. Ngakho-ke, izinto zokuhlunga ze-PTFE zifaneleka kakhulu ukwenza isihlungi esimahhadlahhaza noma esisezingeni eliphezulu, kanye nezinto zokuhlunga zengilazi ezifanele kakhulu ukukhiqizwa. Isihlungi esisebenza kahle noma esisebenza kahle kakhulu. Isihlungi se-fiber HEPA yengilazi esinemininingwane engu-610×610×150mm siphansi kunesihlungi sengilazi esingu-610×610×90mm se-HEPA, futhi ukusebenza kokuhlunga kungcono kunesihlungi sengilazi esingu-610×610×90mm se-HEPA. Njengamanje, intengo yezinto ezihlanzekile ze-PTFE iphakeme kunaleyo ye-glass fiber. Kodwa-ke, uma kuqhathaniswa ne-glass fiber, i-PTFE inokumelana okungcono kokushisa, ukumelana nokugqwala kanye ne-hydrolysis kune-glass fiber. Ngakho-ke, izici ezihlukahlukene kufanele zicatshangelwe lapho kukhiqizwa isihlungi. Hlanganisa ukusebenza kwezobuchwepheshe kanye nokusebenza komnotho.

Izithenjwa:

[1]Liu Laihong, Wang Shihong. Ukuthuthukiswa Nokusetshenziswa Kwezihlungi Zomoya [J]•Ukuhlunga Nokuhlukaniswa, 2000, 10(4): 8-10.

[2] CN Davis Air Filter [M], ehunyushwe ngu-Huang Riguang. I-Beijing: I-Atomic Energy Press, ngo-1979.

[3] I-GB/T6165-1985 indlela yokuhlola ukusebenza kahle kwesihlungi somoya indlela yokudlulisa nokumelana [M]. I-National Bureau of Standards, 1985.

[4]Xing Songnian. Indlela yokutholwa nokusetshenziswa okungokoqobo kwesihlungi somoya esisebenza kahle kakhulu[J]•Izisetshenziswa Zokuvimbela I-Bioprotective Epidemic Prevention, 2005, 26(1): 29-31.

[5]I-Hochrainer. Ukuthuthukiswa okuqhubekayo kwekhawunta yezinhlayiyana

sizerPCS-2000glass fiber [J]•Hlunga Ijenali yeAerosolScience, 2000,31(1): 771-772.

[6]E. Weingartner, P. Haller, H. Burtscher njll. Ukucindezela

I-DropAcrossFiberFilters[J]•Aerosol Science, 1996, 27(1): 639-640.

[7]UMichael JM noClyde Orr. Ukuhlunga-Izimiso Nezinqubo[M].

ENew York: MarcelDekkerInc, 1987•

[8] Zhang Guoquan. I-Aerosol mechanics – isisekelo sethiyori sokususa uthuli nokuhlanzwa [M] • I-Beijing: China Environmental Science Press, 1987.

Isikhathi sokuthumela: Jan-06-2019